Two-Color Injection Molding Machine Application

- The upper template is equipped with two upper molds, and the rotary has two lower molds. When forming, the disc is rotated 180 forward and reverse. It can complete two-color two-material injection molding, or over-molding injection molding machine two-color machine.

- Vertical mold clamping, additional disc, and two independent injection units (independent hydraulic oil circuit) clamping force from 90T to 500T, using complete computer control, low and high hydraulic system, more suitable for the production of general or special Two-color (two-material) molding.

- The turntable adopts hydraulic motor speed control, optional servo motor drive, mechanical positioning device to ensure the accuracy of positioning and the mold and ensure that the molding mold is accurately and quickly closed.

- Two sets of independent mold clamping systems are also available, the movable templates are separated, and different molds can also be formed in two colors and two materials.

Features

- Clamping force: 10T~500T.

- Injection weight: 35g~850g.

- Vertical calmping, vertical injection.

- Rotation stability mult-station design, accuracy of rotation and positioning, convenient taking and placing device.

- We can upgrade to servo motor for customer’s needs.

- The actual energy save 50%~70%.

Parameters

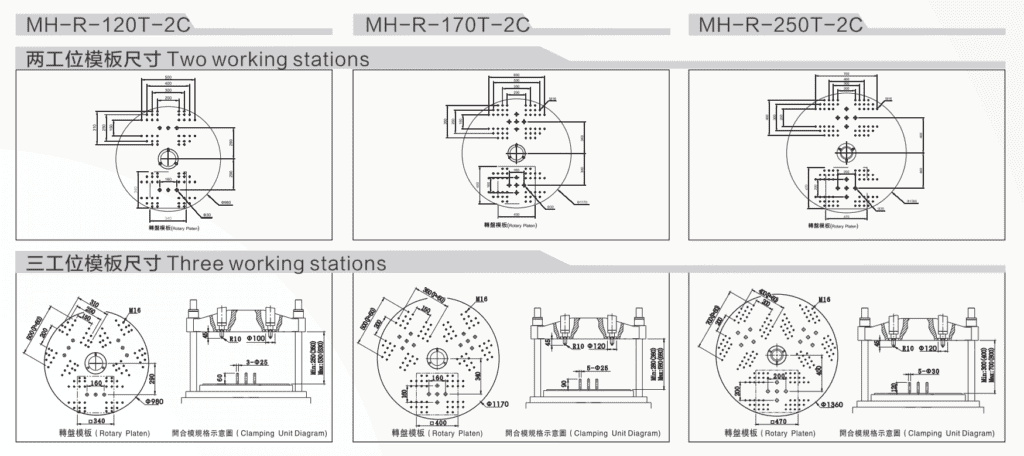

| MODEL | UNIT | MH-R-120T-2C | MH-R-170T-2C | MH-R-250T-2C | |||||

| Option Injection System | Series. No | I A, B | Ⅱ A, B | I B, C | Ⅱ B, C | I C, D, E | Ⅱ C, D, E | ||

|

CLAMPING UNIT |

Clamping Force | KN (tf) | 1176 (120) | 1666 (170) | 2450 (250) | ||||

| Clamping Stroke | mm | 280 | 300 | 400 | |||||

| Min.Mold Thickness | mm | 250 (350) | 280 (380) | 300 (400) | |||||

| Max. Opening | mm | 530 (630) | 580 (680) | 700 (800) | |||||

| Diameter Of Rotary Table | mm | Φ 980 | Φ 1170 | Φ 1360 | |||||

| Ejector Distance | mm | 60 | 90 | 120 | |||||

| Ejector Force | KN (tf) | 17.2 (175) | 26.5 (2.7) | 45 (4.6) | |||||

|

OTHERS |

System Pressure | Mpa (kgf / cm²) | 13.7 (140) | 13.7 (140) | 13.7 (140) | ||||

| Oil Tank Capacity | L | 780 | 860 | 880 | |||||

| Electric Power | KW (HP) | 11 (15) + 11 (15) | 15 (20) + 15 (20) | 18.5 (25) + 22 (30) | |||||

| Machine Dimensions (L×W×H) | M | 2.3×2.1×3.6 | 2.45×2.3×3.9 | 3.6×2.5×4.6 | |||||

| Machine Weight | tf | 7.0 | 9.1 | 17.4 | |||||

| MODEL | UNIT | A | B | ||||||

|

INJECTION UNIT |

Screw Diameter | mm | Φ 25 | Φ 28 | Φ 32 | Φ 28 | Φ 32 | Φ 36 | |

| Theoretical Injection Volume | cm | 63.8 | 80 | 104 | 80 | 104 | 132 | ||

| Injection Weight(PS) | g (oz) | 59.3 (2.1) | 74.4 (2.6) | 96.7 (3.4) | 74.4 (2.6) | 96.7 (3.4) | 122.9 (3.6) | ||

| Injection Speed | Main Injection | mm / s | 206 (120T) | 149 (120T) / 164 (170T) | |||||

| Deputy Injection | mm / s | 166 (120T) | 119 (120T) / 164 (170T) | ||||||

| Max. Injection Pressure. | Mpa (kgf / cm²) | 248 (2530) | 192 (1960) | 153 (1563) | 212 (2170) | 162 (1661) | 128 (1312) | ||

| Screw Rotation Speed | r.p.m | 0~300 | 0~240 | ||||||

| Nozzle Out From Platens | mm | ≧ 45 | ≧ 45 | ||||||

| Motor Power | kw | 3.5 | 5.8 | ||||||

| MODEL | UNIT | C | D | ||||||

|

INJECTION UNIT |

Screw Diameter | mm | Φ 32 | Φ 36 | Φ 40 | Φ 36 | Φ 40 | Φ 45 | |

| Theoretical Injection Volume | cm | 113 | 142 | 176 | 162 | 201 | 254 | ||

| Injection Weight(PS) | g (oz) | 105 (3.7) | 132 (4.6) | 164 (5.8) | 151 (5.3) | 187 (6.6) | 236 (8.3) | ||

| Injection Speed | Main Injection | mm/s | 116 (170T) / 164 (250T) | 134 (250T) | |||||

| Deputy Injection | mm/s | 116 (170T) / 154 (250T) | 123 (250T) | ||||||

| Max. Injection Pressure. | Mpa (kgf / cm²) | 229 (2331) | 181 (1842) | 146 (1492) | 222 (2268) | 180 (1838) | 142 (1452) | ||

| Screw Rotation Speed | r.p.m | 0 – 300 | 0 – 300 | ||||||

| Nozzle Out From Platens | mm | ≧ 45 | ≧ 45 | ||||||

| Motor Power | kw | 6.4 | 10.6 | ||||||

| MODEL | UNIT | E | ||||

|

INJECTION UNIT |

Screw Diameter | mm | Φ45 | Φ50 | Φ55 | |

| Theoretical Injection Volume | cm | 318 | 393 | 475 | ||

| Injection Weight(PS) | g (oz) | 296 (10.4) | 365 (12.8) | 442 (15.6) | ||

| Injection Speed | Main Injection | mm / s | 87 (250T) | |||

| Deputy Injection | mm / s | 80 (250T) | ||||

| Max. Injection Pressure. | Mpa (kgf / cm²) | 218 (2226) | 177 (1803) | 146 (1490) | ||

| Screw Rotation Speed | r.p.m | 0~300 | ||||

| Nozzle Out From Platens | mm | ≧ 45 | ||||

| Motor Power | kw | 14.2 | ||||

Specification for a complete clamping (there are another specifications for independent clamping cylinder)

———————————————————— Sample Display ————————————————————

How many types of two-color injection molding machines are there?

The two-color plastic injection molding machine has two rear and two front molds (the structure of the two front molds is the same). Two rear molds are installed parallel to the back mold installation part of the injection molding machine. Two front molds are installed in the front mold installation part. The double color injection molding machine has two injection nozzles (two barrels), two dryers, and two kinds of injection materials.

A two-color plastic injection machine is a kind of machine that can produce plastic products with different materials and different colors.

Two-color injection molding machine through the injection device and technology to inject two different materials into the same set of mold injection finished products.

Two-color plastic injection machine is the same two-color main color machine injection of two plastic materials, then two moldings, but the development of plastic mold production once. This operation is usually done by only one set of molds and requires a particular two-color injection molding machine. With the cooperation of two-color molds, the Chinese two-color injection molding machine produces plastic products with two colors or materials, improving the finished products’ experience and beauty.

The requirements of a double colour injection molding machine are relatively complex for the mold, and its structure and characteristics are different from those of single-color molds.

Types of two-color plastic injection molding machine

According to the structure, two-color can be divided into the core rotation, core retraction, and slide rotation. At present, core rotation is widely used in the market. Core rotation split type is an injection molding machine used on two splits by alternate cycles to achieve two-color product injection molding. Another form of core rotation is the conjoined type, i.e., injection molding of two-color products in a pair of molds.

To avoid the mother mold from rubbing the colloid of the first molding product during the second injection, it can be appropriately designed partially to avoid hollow and master the sealing strength to prevent the deformation of the product under significant impact.

The development of two-color plastic injection molding machine types

At present, double colour injection moulding machines have been widely used in our lives, such as electronic products, toys, medical products, etc. Therefore, two-color molds are also developing gradually. With the continuous innovation of science and technology, multicolor injection molding machines have appeared and are overgrown. Two-color molds and multicolor molds will be widely used in our daily lives.