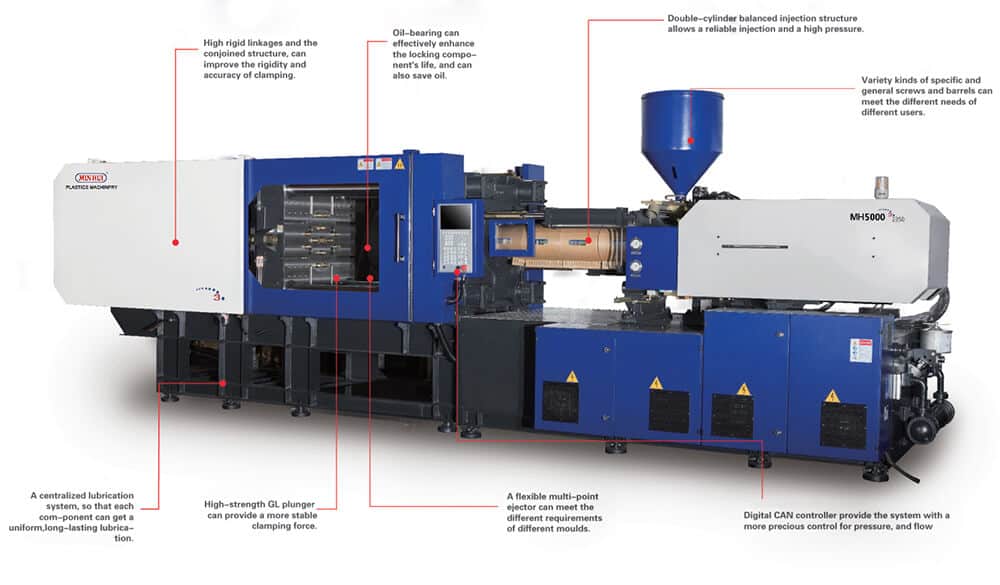

Horizontal Injection Molding Machine Description

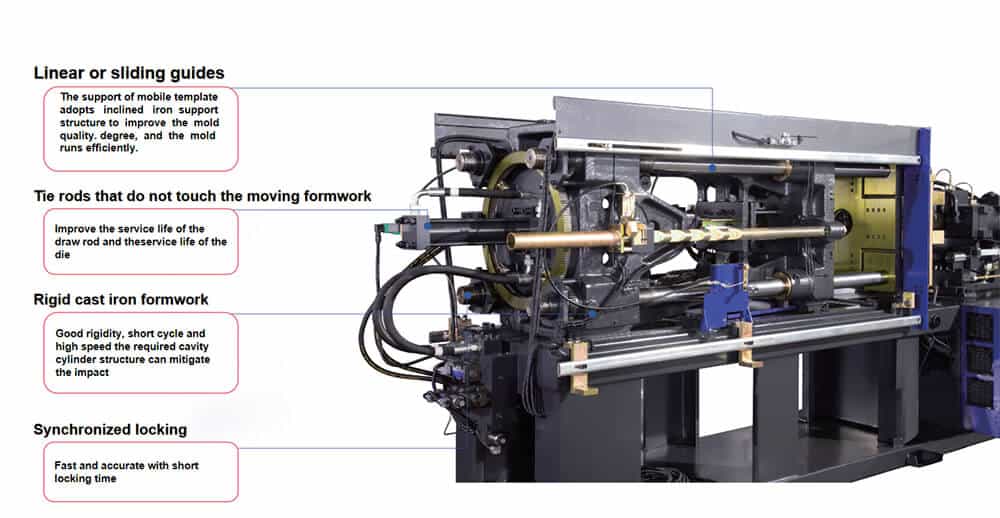

Horizontal Injection Molding Machine Clamping Unit

Specification type: According to the user’s dfferent choice, plasticizing part can provideA, B two sets of specifications injection system specifications.

Specification type: According to the user’s dfferent choice, plasticizing part can provideA, B two sets of specifications injection system specifications.

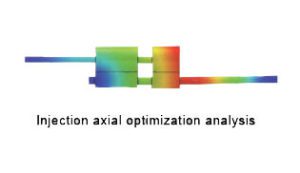

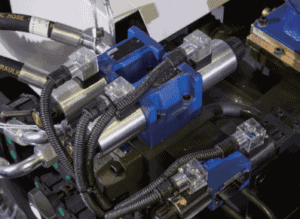

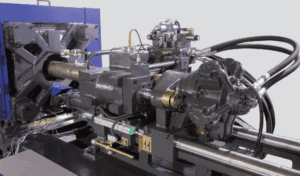

Structural design:The injection unit adopts double cylinder balance injecion structure to make the injection reliable, the pressure is strong, and the nozzle alignment device can adjust the structure of the nozzle and the center of the mold through a simple operation.

Structural design:The injection unit adopts double cylinder balance injecion structure to make the injection reliable, the pressure is strong, and the nozzle alignment device can adjust the structure of the nozzle and the center of the mold through a simple operation.

Powerful function: Low speed and high torque five star motor pre – plastic device to ensure the system good feed, plasticizing capacity, to adapt to diferent plastics

Control mode: The pressure and flow control of hydraulic system, the system accuracy is improved by more than two times according to circumstances.

Control mode: The pressure and flow control of hydraulic system, the system accuracy is improved by more than two times according to circumstances.

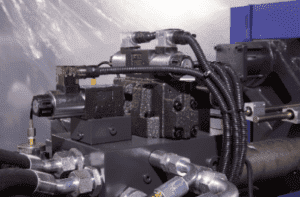

Piping layout: Piping layout is more reasonable and beautiful, easy maintenance

Piping layout: Piping layout is more reasonable and beautiful, easy maintenance

Hydraulic components: In order to meet the technical requirements of large flow pump,the speed of the whole machine is improved, the valve diameterand the pipe diameter are increased.

Hydraulic components: In order to meet the technical requirements of large flow pump,the speed of the whole machine is improved, the valve diameterand the pipe diameter are increased.

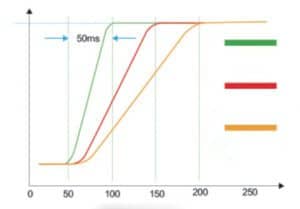

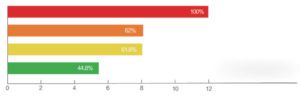

Servo Motordynamical Control System

High response, high torque servo drive motor with pressure, flow closed loop control, so that the whole reaction speed, control accuracy, energy efficiency greatly improved. Compared with the general market, the servo energy-saving injection molding machine has the advantages of higher repeability, smaller pressure flow fluctuation, more obvious energy saving effect, and faster response speed.

- “TFT” color display system, provide input data and fault alarm, using a large screen L ED display, support multi language system

- All digital CAN control mode of the system pressure, flow control is more accurate, itelligent “brain” of convenient use, convenient maintenance, accurate operation, can be directly input pressure,speed, position, time and the barrel temperature data from the computer, a computer program to monitor safety protection, prevent automatic clamping, avoid accidents.

- High quality electrical components, enhanced hardware circuit, anti-interference ability is stronger, more reliable and stable operation.

Horizontal Injection Molding Machine Specification

Technical Data Stock Series

| SPECIFICATION | UNIT | MH140 | MH180 | MH220 | MH250 | ||||||||

| INJECTION UNIT | A | B | C | A | B | C | A | B | C | A | B | C | |

| Screw Diameter | mm | 36 | 40 | 45 | 40 | 45 | 50 | 45 | 50 | 55 | 50 | 55 | 60 |

| Length/Diameter Ratio | L/D | 23.1 | 20.8 | 18.4 | 22.0 | 19.5 | 17.6 | 22.3 | 20.1 | 18.3 | 22.0 | 20.0 | 18.3 |

| Theoretical Injection Pressure | MPa | 185 | 150 | 119 | 215 | 169 | 137 | 190 | 154 | 127 | 215 | 178 | 149 |

| Theoretical Shot Volume | cm3 | 198.4 | 244.9 | 310.0 | 282.6 | 357.7 | 441.6 | 389.5 | 480.8 | 581.8 | 588.8 | 712.4 | 847.8 |

| Injection Welght(PS) | g | 186.5 | 230.2 | 291.4 | 265.6 | 336.2 | 415.1 | 366.1 | 452.0 | 546.9 | 553.4 | 669.6 | 796.9 |

| Injection Rate(PS) | g/s | 91.4 | 112.8 | 142.8 | 112.2 | 142.0 | 175.3 | 138.5 | 171.0 | 206.9 | 157.4 | 190.4 | 226.6 |

| Plasticzing Capacity | g/s | 12.9 | 17.9 | 25.0 | 17.8 | 25.0 | 33.8 | 23.0 | 31.2 | 38.8 | 30.4 | 37.9 | 46.4 |

| Maximum Screw Speed | rpm | 205 | 205 | 180 | 180 | ||||||||

| CLAMPING UNIT | |||||||||||||

| Clamp Tonnage | KN | 1200 | 1600 | 2180 | 2500 | ||||||||

| Toggle Stroke | mm | 360 | 430 | 490 | 540 | ||||||||

| Space Between Tie Bars(H x V) | mm | 414×414 | 472×472 | 532×532 | 581 x581 | ||||||||

| Max.Mold Height | mm | 450 | 520 | 550 | 580 | ||||||||

| Min.Morld Height | mm | 130 | 150 | 150 | 220 | ||||||||

| Elector Tonnage | KN | 45.2 | 45.2 | 70.7 | 70.7 | ||||||||

| Ejector Stroke | mm | 122 | 142 | 142 | 152 | ||||||||

| Ejector Number | piece | 5 | 5 | 9 | 9 | ||||||||

| OTHERS | |||||||||||||

| System Pressure | MPa | 16 | 16 | 16 | 16 | ||||||||

| Pump Moter Power | KW | 18.5 | 22 | 22 | 30 | ||||||||

| Heating Powre | KW | 9.4 | 9.6 | 14 | 16.5 | ||||||||

| Hopper Capacity | Kg | 25 | 25 | 50 | 50 | ||||||||

| Machine Dimensions (LxWxH) | m | 4.88×1.21 x2.04 | 5.4×1.31 x2.08 | 5.9×1.32×2.1 | 6.42×1.48×2.18 | ||||||||

| Oil Tank Capacity | L | 197 | 248 | 280 | 359 | ||||||||

| Machine Weight | T | 4.5 | 5.3 | 6.9 | 8.3 | ||||||||

| SPECIFICATION | UNIT | MH280 | MH330 | MH420 | MH500 | ||||||||||

| INJECTION UNIT | A | B | C | A | B | C | A | B | C | D | A | B | C | D | |

| Screw Diameter | mm | 55 | 60 | 65 | 60 | 65 | 70 | 65 | 70 | 75 | 80 | 70 | 80 | 85 | 90 |

| Length/Diameter Ratio | L/D | 21.7 | 19.9 | 18.4 | 21.7 | 20.0 | 18.6 | 21.5 | 20.0 | 18.7 | 17.5 | 22.6 | 19.8 | 18.6 | 17.6 |

| Theoretical Injection Pressure | MPa | 219 | 184 | 157 | 213 | 182 | 157 | 211 | 182 | 158 | 139 | 194 | 149 | 132.0 | 117.0 |

| Theoretical Shot Volume | cm3 | 712.4 | 847.8 | 157.0 | 990.5 | 1162.5 | 1348.2 | 1328.3 | 1540.5 | 1768.5 | 2012.1 | 1692.5 | 2210.6 | 2495.5 | 2797.7 |

| Injection Welght(PS) | g | 669.6 | 796.9 | 935.3 | 931.1 | 1092.7 | 1267.3 | 1248.6 | 1448.1 | 1662.4 | 1891.4 | 1590.9 | 2077.9 | 2345.8 | 2629.9 |

| Injection Rate(PS) | g/s | 206.1 | 245.2 | 287.8 | 211.5 | 248.2 | 287.9 | 258.7 | 300.0 | 344.4 | 391.9 | 358.6 | 468.4 | 528.8 | 592.8 |

| Plasticzing Capacity | g/s | 46.5 | 56.9 | 68.6 | 53.7 | 64.8 | 81.3 | 54.4 | 68.2 | 84.2 | 100.2 | 68.4 | 100.5 | 118.6 | 141.4 |

| Maximum Screw Speed | rpm | 230 | 225 | 190 | 190 | ||||||||||

| CLAMPING UNIT | |||||||||||||||

| Clamp Tonnage | KN | 2800 | 3280 | 3880 | 4800 | ||||||||||

| Toggle Stroke | mm | 590 | 640 | 700 | 780 | ||||||||||

| Space Between Tie Bars(H x V) | mm | 631×631 | 681×681 | 731×731 | 820×800 | ||||||||||

| Max.Mold Height | mm | 630 | 680 | 730 | 780 | ||||||||||

| Min.Morld Height | mm | 230 | 250 | 280 | 320 | ||||||||||

| Elector Tonnage | KN | 70.7 | 70.7 | 125.6 | 125.6 | ||||||||||

| Ejector Stroke | mm | 152 | 162 | 183 | 203 | ||||||||||

| Ejector Number | piece | 13 | 13 | 13 | 17 | ||||||||||

| OTHERS | |||||||||||||||

| System Pressure | MPa | 16 | 16 | 16 | 16 | ||||||||||

| Pump Moter Power | KW | 37.0 | 37 | 45 | 55 | ||||||||||

| Heating Powre | KW | 17.8 | 20.8 | 24.8 | 31 | ||||||||||

| Hopper Capacity | Kg | 50 | 50 | 50.0 | 50 | ||||||||||

| Machine Dimensions (LxWxH) | m | 6.53×1.64×2.15 | 7.01×1.7×2.15 | 7.46x 1.85×2.20 | 8.15x 1.99×2.36 | ||||||||||

| Oil Tank Capacity | L | 368 | 409 | 547.0 | 615 | ||||||||||

| Machine Weight | T | 11 | 13 | 15 | 19 | ||||||||||

| SPECIFICATION | UNIT | MH700 | MH800 | MH1000 | |||||||||

| INJECTION UNIT | A | B | C | D | A | B | C | D | A | B | C | D | |

| Screw Diameter | mm | 80 | 85 | 90 | 100 | 90 | 100 | 110 | 120 | 100 | 110 | 120 | 130 |

| Length/Diameter Ratio | L/D | 22.0 | 20.7 | 19.6 | 17.6 | 24.4 | 22.0 | 20.0 | 18.3 | 24.2 | 22.0 | 20.2 | 18.6 |

| Theoretical Injection Pressure | MPa | 184 | 163 | 146 | 118 | 211 | 171 | 141 | 119 | 211 | 174 | 146 | 125 |

| Theoretical Shot Volume | cm3 | 2361.3 | 2665.7 | 2988.5 | 3689.5 | 3179.3 | 3925.0 | 4749.3 | 5652.0 | 4356.8 | 5271.7 | 6273.7 | 7362.9 |

| Injection Welght(PS) | g | 2219.6 | 2505.7 | 2809.2 | 3468.1 | 2988.5 | 3689.5 | 4464.3 | 5312.9 | 4095.3 | 4955.4 | 5897.3 | 6921.1 |

| Injection Rate(PS) | g/s | 448.7 | 506.5 | 567.8 | 701.0 | 516.1 | 637.2 | 771.0 | 917.6 | 651.2 | 788.0 | 937.8 | 1100.6 |

| Plasticzing Capacity | g/s | 81.7 | 96.3 | 114.9 | 141.8 | 106.8 | 131.9 | 159.6 | 189.9 | 136.1 | 164.7 | 196.0 | 230.0 |

| Maximum Screw Speed | rpm | 140 | 127 | 131 | |||||||||

| CLAMPING UNIT | |||||||||||||

| Clamp Tonnage | KN | 6800 | 8800 | 10000 | |||||||||

| Toggle Stroke | mm | 900 | 1040 | 1220 | |||||||||

| Space Between Tie Bars(H x V) | mm | 880×880 | 1000×1000 | 1160×1160 | |||||||||

| Max.Mold Height | mm | 880 | 1000 | 1160 | |||||||||

| Min.Morld Height | mm | 380 | 420 | 500 | |||||||||

| Elector Tonnage | KN | 180.9 | 212.3 | 246.2 | |||||||||

| Ejector Stroke | mm | 243 | 283 | 323 | |||||||||

| Ejector Number | piece | 21 | 21 | 21 | |||||||||

| OTHERS | |||||||||||||

| System Pressure | MPa | 16 | 16 | 16 | |||||||||

| Pump Moter Power | KW | 55 | 37+37 | 37+55 | |||||||||

| Heating Powre | KW | 44.0 | 61.0 | 74.0 | |||||||||

| Hopper Capacity | Kg | 100 | 100 | 100.0 | |||||||||

| Machine Dimensions (LxWxH) | m | 9.57×2.2×2.7 | 10.9×2.5×2.8 | 12×2.5×2.8 | |||||||||

| Oil Tank Capacity | L | 668 | 949 | 1333.0 | |||||||||

| Machine Weight | T | 29 | 38 | 51 | |||||||||

————————————————————- Sample Display ————————————————————-