Rotary Injection Molding Machine 160T Video

Rotary Injection Molding Machine 160T Application

- Super ample mold installation space, using four-column design, no interference of the middle column.

- High-precision positioning, so that the upper and lower molds are more accurately molded together, 180 degrees of alternate rotation of the disc, sizeable operating space, easy to take out and put in the insert, high production efficiency.

- Automatic inserting and removing devices can be added to achieve the whole automatic operation of the machine.

Feature

- Double-station (or three-station) turntable table, stable rotation, and accurate positioning can improve production efficiency by up to 30%-50%.

- Comparable pressure and flow oil pressure circuit design.

- The injection system adopts electronic ruler control, multi-stage pressure, and speed adjustment can be set according to the requirements of the product, easy to adjust. Ensure the accuracy of the product.

- High precision P.I.D. temperature control, stable temperature control in each section, slight error.

- The injection system is designed with double injection cylinders, double seat cylinders, and double guide pillars, with smooth movement and high injection precision.

- Special screw and tube set design, suitable for different injection process requirements.

- Configuration of high torque, low noise hydraulic motor, so the plasticizing ability is more excellent.

- High-quality self-lubricating bearings are used in movable parts to make machine maintenance easier.

Advantages of Rotary Vertical Injection Molding Machine

- One machine with multiple molds improves production efficiency and saves time.

- Small investment, high return rate, one machine can top the efficiency of multiple machine products.

- Can realize automation, reduce labor cost, and higher efficiency.

- The machine has a long service life and is a fixed asset for customers.

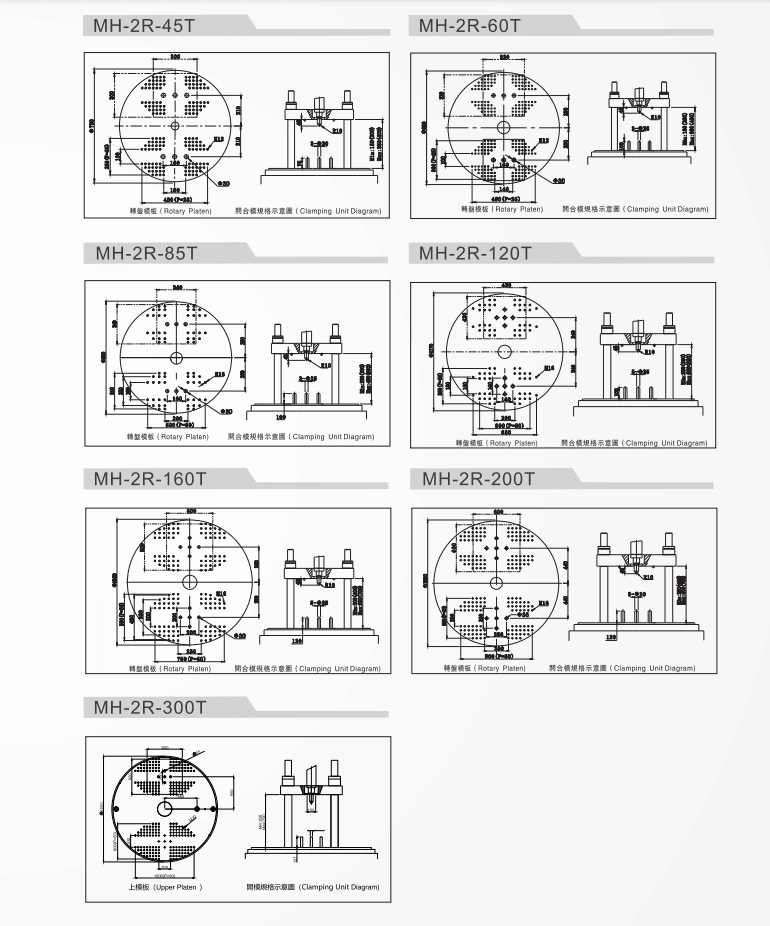

Parameter

| MODEL | UNIT | MH-2R-160T | |||

|---|---|---|---|---|---|

| INJECTION UNIT | Screw Diameter | mm | Φ 45 | Φ 50 | Φ 55 |

| Theoretical Injection Volume | cm | 318 | 393 | 475 | |

| Injection Weight (PS) | g (oz) | 296 (10.4) | 365 (12.8) | 442 (15.6) | |

| Max.Injection Pressure | Mpa (kgf / cm2) | 218 (2226) | 177 (1803) | 146 (1490) | |

| Injection Rate | cm3 / s | 178 | 220 | 266 | |

| Injection speed | mm / s | 112 | |||

| Speed Improvement | mm / s | 290 (60T) / 200 (85T) / 168 (160T) | |||

| Screw Rotation Speed | r.p.m | 0~300 | |||

| Nozzle Out From Platens | mm | ≥ 45 | |||

| CLAMPING UNIT | Clamping Force | KN (tf) | 1568 (160) | ||

| Clamping Stroke | mm | 300 | |||

| Min. Mold Thickness | mm | 300 (400) | |||

| Max. Opening | mm | 600 (700) | |||

| Max. Mold Site (L×W) | mm | 500×500 | |||

| Diameter Of Rotary Table | mm | Φ 1360 | |||

| Ejection Distance | mm | 120 | |||

| Ejector Force | KN (tf) | 45 (4.6) | |||

| OTHERS | System Pressure | Mpa (kgf / cm2) | 13.7 (140) | ||

| Oil Tank Capacity | L | 850 | |||

| Motor Power | KW (HP) | 18.5 (25) | |||

| Machine Dimensions (L×W×H) | M | 2.7×2.2×4.5 | |||

| Machine Weight | tf | 9.4 |

Specification for a complete clamping (there’re another specification for independent clamping cylinder)

————————————————————- Sample Display ————————————————————-