Standard Injection Molding Machine Application

- MH standard machine, also called power cord molding machine, suitable for insert molding of available electrical plugs and electronic parts.

- Two-stage or three-stage temperature control, step-less adjustment of injection speed, back pressure, etc., are more suitable for precision plastic parts molding.

- Fast mold clamping/low-pressure, slow mold closing. When the mold lock is abnormal, the mold will be opened automatically. This particular safety design can protect the mold.

- The lower mold is fixed, the upper mold is movable, which has a good positioning of the molded insert in the mold. The finished product has a hydraulic ejector device, which is very convenient and easy to take out.

Feature

- Clamping force: 15T to 35T

- Injection weight: 35g to 90g

- Vertical four columns clamping, vertical injection.

- Suitable for insert injection molding process.

- We can upgrade to servo motor for customer’s needs.

- The actual energy save 50%~ 70%.

Standard Injection Molding Machine Specification

| MODEL | UNIT | MH-15T | MH-20T | MH-35T | |||||

|

INJECTION UNIT |

Screw Diameter | mm | Φ 26 | Φ 28 | Φ 22 | Φ 28 | Φ 26 | Φ 28 | Φ 32 |

| Injection Pressure | Kgf / cm² | 1715 | 1098 | 1416 | 875 | 1677 | 1446 | 1107 | |

| Theoretical Shot Volume | cm³ | 55 | 65 | 40 | 65 | 61 | 71 | 93 | |

| Max. Shot Weight. | g / oz | 51.2 / 1.8 | 59.4 / 2 | 36.7 / 1.29 | 59.4 / 2 | 56.6 / 2 | 65.6 / 2.3 | 85.7 / 3 | |

| Injection Rate | cm³ / s | 50 | 59 | 36 | 59 | 41 | 48 | 62 | |

| Screw Stroke | mm | 105 | 105 | 116 | |||||

| Screw Rotation Speed | rpm | 0-215 | 0-138 | 0-148 | |||||

| Nozzle Contact Force | Tons | — | 3.5 | 3.5 | |||||

| Nozzle Retraction Stroke | mm | — | 120 | 150 | |||||

| Stages of Temperature Control | 2 | 2 | 3 | ||||||

|

CLAMPING UNIT |

Clamping Force | Tons | 15 | 20 | 35 | ||||

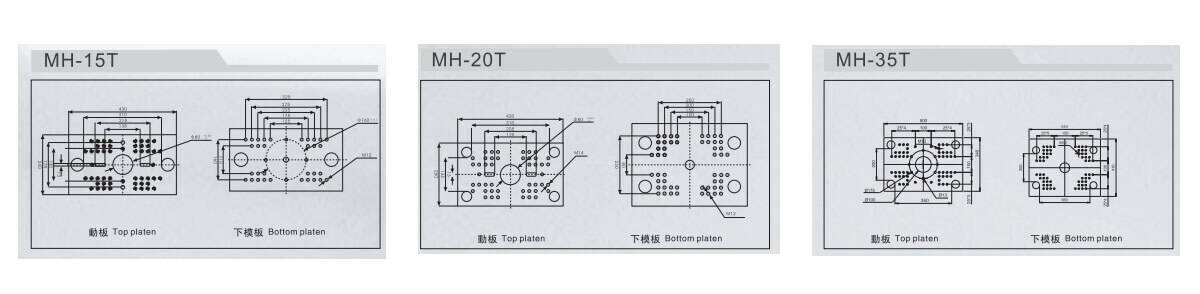

| Platen Size | mm | 280×250 | 420×250 | 500×340 | |||||

| Distance between Columns | mm | 310 | 310×130 | 360×200 | |||||

| Min. Mold Thickness. | mm | 35 | 35 / 100 | 60 / 145 | |||||

| Opening Stroke | mm | 198 | 198 | 215 | |||||

| Max. Mold Opening Distance. | mm | 233 | 233 / 298 | 275 / 360 | |||||

| Ejector force | Tons | 1.3 | 1.3 | 1.3 | |||||

| Ejector stroke | mm | 35 | 35 | 35 | |||||

|

OTHERS |

Max. Hydaulic Pressure. | Kgf / cm² | 140 | 140 | 140 | ||||

| Oil pump output | cc / rec | 23 | 23 | 31 | |||||

| Cooling Water Consumption | L / h | 400-600 | 400-600 | 500-700 | |||||

| Motor Power | Kw | 2.2 (3 HP) | 2.2 (3 HP) | 4 (5.5 HP) | |||||

| Barrel Heating Power | Kw | 2 | 2 | 2.4 | |||||

| Total Wattage | Kw | 4.2 | 4.2 | 6.4 | |||||

| Machine Weight Net | Kg | 650 | 800 | 1200 | |||||

| Machine Dimensions (L×W×H) | m | 1.15×0.75×2.15 | 1.2×0.8×2.2 | 1.45×0.9×2.5 | |||||

| Shipping Weight Gross | Kg | 650 | 850 | 1300 | |||||

| Shipping dimensions (L×W×H) | m | 1.4×1.0×2.3 | 1.5×1.0×2.3 | 1.6×1.1×2.2 | |||||

Specification for a complete clamping (there’re another specification for independent clamping cylinder)

————————————————————- Sample Display ————————————————————-