Many people are confused about the difference between vertical and horizontal injection molding machines.

The two types of injection machines have different advantages. But they also have their disadvantages. Both can be used for various industries, including toys, household appliances, and electronic devices.

To choose a suitable one for your business, you need to know more details about them in advance. That’s why we’ve prepared this article for all of you who want to learn more about these two kinds of equipment undoubtedly! Let’s start from the beginning.

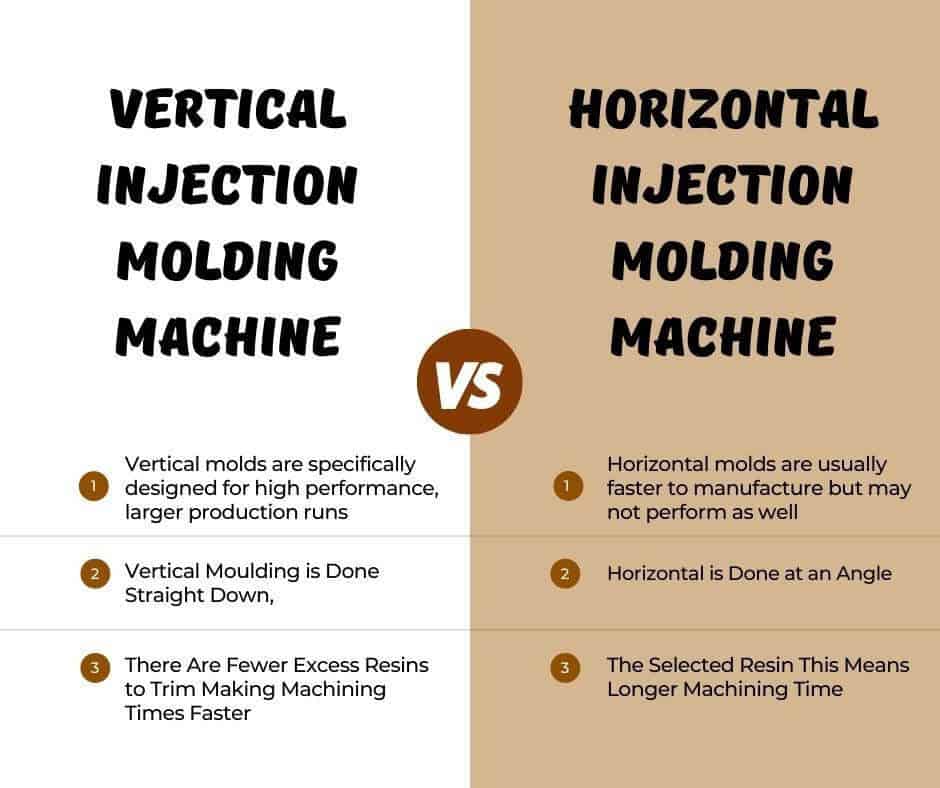

Comparison of Horizontal and Vertical Injection Molding Machine (with Infographic)

Nowadays, a lot of people always say the injection molding machine is viral in all aspects. But there are a few questions worth considering: does it have its shortcomings? What kind of machines do we need? How many kinds? They may vary from person to person’s thinking and understanding. Vertical injection molding machines and horizontal injection molding machines have both advantages and disadvantages.

Here are some common types of injection molding machines:

The differences between vertical injection molding machines and horizontal injection molding machines are the different kinds of clamping. It is one of the essential parts of an injection molding machine.

As far as the structure is concerned, vertical injection molding machines have a straightforward system. The main engine is the clamping cylinder with a small motor installed inside. In some cases, there are more than one of them. It can be used on straight or curved molds and also on both solid and hollow products.

The purpose of using a horizontal injection molding machine is to realize a variety of shapes and improve the efficiency of injection molding. The horizontal injection molding machine uses a clamping bar with vertical strokes. So, this is important for protecting the internal organs in an automatic pressing machine when used for large-scale production lines.

The primary difference between Vertical and Horizontal Injection Molding Machine

Here we must think carefully about why it is called a “horizontal injection molding machine.” Because the clamping cylinder, which is the critical part of the injection molding machine, is horizontal. From this explanation, we know that it must be arranged on either side of the product (the front and back sides). We may find that if there are two or more products in one line, it will make no sense to arrange the clamping cylinder in line with the side of the products.

The two main types of injection molding machines are vertical injection molding machines and horizontal injection molding machines. How do they differ? The way to understand them is when you want to make an object. Therefore, it is better to choose a kind of machine according to its situation. Vertical injection molding machines are mainly used to make refined products because the bottom of the device is fixed to the ground and can be installed on a vertical plane.

Vertical Injection Molding Machine | Horizontal Injection Molding Machine |

Vertical injection molding machines have a straightforward structure. The main machine is the clamping cylinder with a small motor installed inside. | Horizontal injection molding machine is to realize a variety of shapes and improve the efficiency of the injection molding. |

It can be used on straight or curved molds and solid and hollow products. | The horizontal injection molding machine uses a clamping bar with vertical strokes, which is essential for protecting the internal organs in an automatic pressing machine used for large-scale production lines. |

How to decide whether you should choose vertical or horizontal injection molding?

It means that if you want to make a square block, no matter how much shape processing you do, there will always be corners. So, what should we do? You can use the vertical injection molding machine to make it.

It is also suitable for making square molds at home, like square ice molds. We all do not want our model of ice cream to collapse because of its corners. But if you’re going to make some other shapes, the vertical injection machine cannot be used; otherwise, the bottom will be in the air.

The horizontal injection molding machine can make products of various shapes, which makes it popular among customers. And the clamping is always flat (from left to right). So, it means that if there are two or more products. They will not conflict with each other when you use them together on one line. This will make the production more efficient.

When you should select vertical molding machine?

- Vertical injection molding is a lower cost, higher volume process

- The parts are more substantial and have better surface finishes

- Greater product variety because it can change the molds more quickly

- Reduces production timelines

- Decreases the cost of a mold’s fabrication and assembly

- Maximizes volume within a limited space

- Provides faster time from design to tooling

When you should select Horizontal molding machine?

- Horizontal injection moldings have more consistency in their products with more minor changes from batch to batch. They also require less vertical space, which makes them easier to transport.

- Horizontal injection molding is much faster to produce, but the quality may not be as good.

- Horizontal injection molding can have greater detail in the molds themselves, which means parts are more detailed.

Advantages of vertical over horizontal machines in the manufacturing process

The advancements in the manufacturing sector have changed the way the fabrication process is done. Today, there are many differences between vertical and horizontal machines that can manufacture products or parts of products.

Reports show that labor cost has increased by more than 10% for companies all over the world. Companies look for ways to cut their cost while manufacturing their products. Some of the manufacturing processes involve vertical machines that can perform multiple operations at one time. Thus, decreasing costs for companies using these types of devices. With the use of horizontal machines, it takes more time per operation.

Vertical machines are very efficient concerning human interference required to manufacture a product. Vertical devices are more compact and precise as compared to traditional horizontal machines. Horizontal machines need more space as compared to vertical machinery. There is also a minor breakdown with vertical machinery as compared to horizontal machinery.

Final Words

In conclusion, we all know that vertical and horizontal machines are both indispensables if you want to do injection molding. But it is still necessary to consider the step by step before choosing a kind of machine. If you can choose according to your own needs, perhaps it will be much better than choosing blindly.

In short, the horizontal injection molding machine is more suitable for large-scale production lines. On the contrary, you can use it to make a variety of things at home because it is easy to install and operate if you want to make a lot of molds with different shapes. So, I believe that it will give you a better effect with the horizontal injection molding machine.