Umbrella Rib Plastic Injection Molding Machine

Min-Hui has the umbrella manufacturing process for many years research, development of rib machine based on the forefront of the industry.

Previous slide

Next slide

Umbrella Rib Plastic Injection Machine's Description

Application

Advantages

Feature

Specification

Application

- Umbrella bone machine, particular injection molding machine, this umbrella bone rod special injection molding machine allows the two sets of injection molding units arranged side by side to adjust the mutual distance through the slide rail structure and the screw structure. The distance between the holes adjusts the distance between the two sets of injection molding units, which facilitates simultaneous injection of the two holes that need to be injected at both ends of the umbrella rib rod, which is convenient and quick, reduces the process, improves the production efficiency, and saves the production cost.

Advantages

- Built-in pressure tracking device, fast injection rate, stable injection pressure quality, and the second injection pressure-holding design, so that the product high quality, high precision.

- All electrical components are brand-name products. Product quality is guaranteed.

- Fast mold closing, slow speed, low-pressure mold locking action device can ensure mold safety, fast speed, increase production.

- Material tube lift, easy to clear the material, to increase operating efficiency.

- Electric eye protection device, no misoperation, to maintain operator safety.

- Small batch trial production, simple mold structure, low cost, and easy to unload.

Feature

- Vertical Clamping, vertical injection.

- Ensure that the injection molding on the same plane, synchronous rib formed at two ends.

- Injection of the relative effective distance, can be arbitrarily adjusted.

- Convenient adjustment dimension stability, applicable to arbitrary size umbrella processing.

- Disposable two molding, reduce the process, more efficient.

Specification

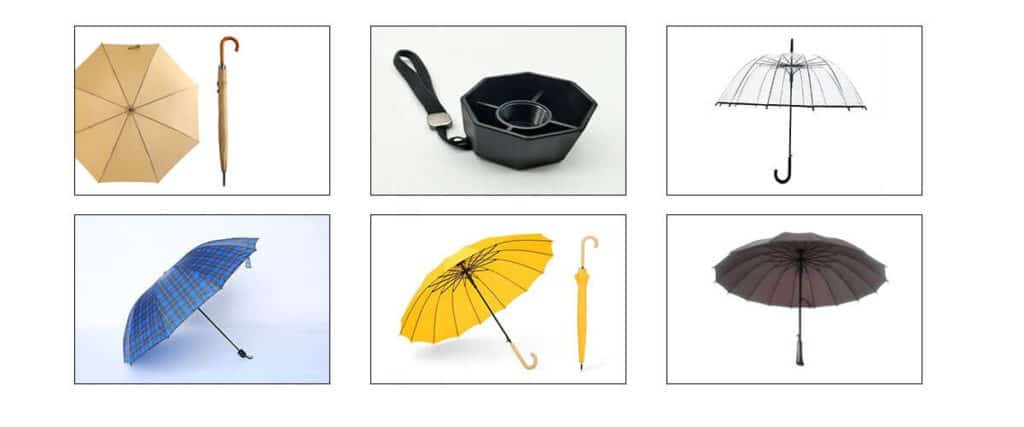

Umbrella Rib Injection Sample Display