Rotary Table Injection Molding Machine

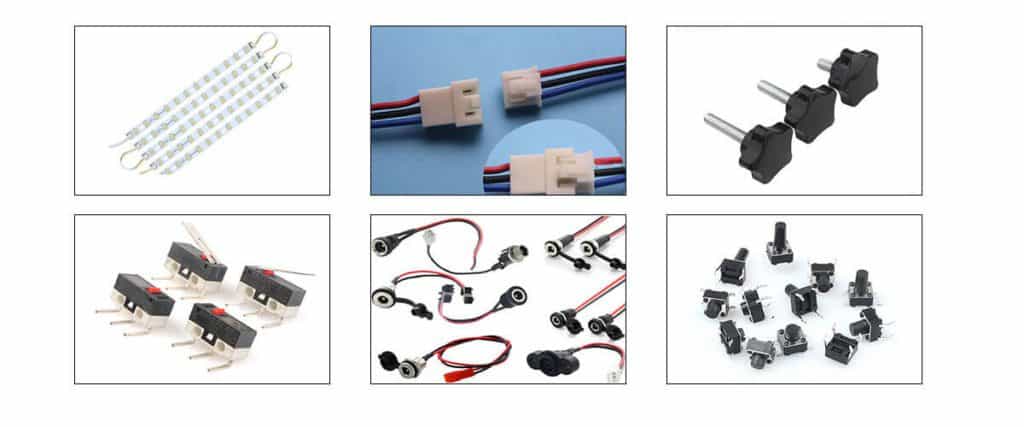

Vertical rotary plastic injection molding machine is suitable for producing automotive parts, energy-saving lamp heads. Golf balls, eyeglass holder nosepiece, LED brackets, and other metal bodies and plastic products forming work of appliance of direct contact with the public, can do fully automatic workflow operation, high efficiency, and low cost.

Rotary Injection Machine's Description

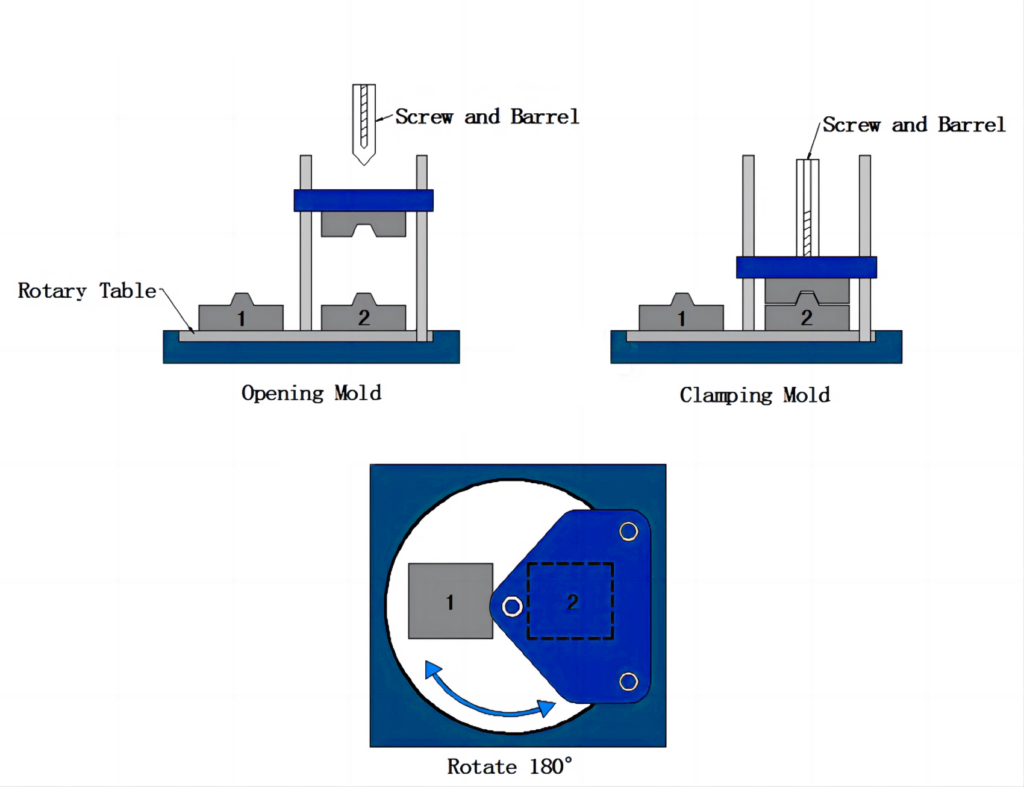

- The advantage of the rotary plastic injection molding machine is that it can choose double-station or three-station, which means it can have one upper mold, two or three lower molds. The operator puts the inserts here, and the clamping mechanism closes the mold to make the product. Improve efficiency, and save labor costs by completing the operation by one person.

- Super ample mold installation space, using four-column design, no interference of the middle column.

- High-precision positioning, so that the upper and lower molds are more accurately molded together, 180 degrees of alternate rotation of the disc, sizeable operating space, easy to take out and put in the insert, high production efficiency.

- Automatic inserting and removing devices can be added to achieve the whole automatic operation of the machine.

- Rotary table injection molding machine with multiple molds improves production efficiency and saves time.

- Small investment, high return rate, one machine can top the efficiency of multiple machine products.

- Can realize automation, reduce labor cost, and higher efficiency.

- The machine has a long service life and is a fixed asset for customers.

vertical injection molding machine with rotary table, also known as rotary injection molding machine, multi-station injection molding machine, its function is more than twice of the vertical injection molding machine, through a machine to improve production efficiency (one set of upper mold, three sets of lower mold, can do more) vertical mold closing, vertical injection, easy to put the product.

High-efficiency disc gear transmission is carried by plane self-lubricating wear-resistant sheet, cooling water adopts central synchronous water transportation device (water pipe can synchronously rotate 360 degrees or 180 degrees forward and reverse water supply device, complete cooling mold program) rotating fast and accurate positioning, using positioning cylinder positioning, high positioning accuracy, high safety performance, end positioning does not fit the mold, protecting the regular use of the mold.

Vertical rotary plastic injection molding machine is suitable for producing automotive parts, energy-saving lamp heads. Golf balls, eyeglass holder nosepiece, LED brackets, and other metal bodies and plastic products forming work of appliance of direct contact with the public, can do fully automatic workflow operation, high efficiency, and low cost.

The machine surface is chrome plated to prevent rust, beautiful and durable. The power section is available with hydraulic motor and servo motor, or higher configuration according to the customer’s product and requirements.V

- Clamping force: 45T to 500T.

- Injection weight: 35g to 850g.

- Vertical four columns clamping, vertical injection.

- 1 top mold, 2 bottoms mold design, turn out the clamping area by Rotation.

- Put insert part into outer mold and inner mold injection at the same time.

- We can upgrade to servo motor for customer’s need, the actual energy save 50% ~ 70%.

- Robots or workers only need to work in one position within the non-working mold, which improves safety.

- The reserved position next to the machine allows easy addition of automation devices and the unique design of low noise machine operation.

- This injection molding machine is suitable for molding plastic materials with inserts, such as motor rotor, lithium battery parts molding, click rotor, etc.

- Ultra-low operating table, the overall height of the machine is reduced.

- Super ample mold installation space, with four-column machine design, no column interference in the middle.

- 180-degree alternate rotation of the disc, sizeable operating space, easy to pick and place inserts, and high production efficiency.

- The machine can be equipped with automatic inserting and removing devices to achieve fully automatic operation. It is more convenient to operate and connect with automation to increase production capacity.

- 2 stations for the disc, 3 or 4 stations can be selected for special needs to achieve more convenient operation.

- The standard disc is a vertical three-column direct clamping die with special mold requirements. It can also be a vertical four-column immediate clamping die.

- Double-station (or three-station) turntable table, stable rotation, and accurate positioning can improve production efficiency by up to 30%-50%.

- Comparable pressure and flow oil pressure circuit design.

- The injection system adopts electronic ruler control, multi-stage pressure, and speed adjustment can be set according to the requirements of the product, easy to adjust. Ensure the accuracy of the product.

- High precision P.I.D. temperature control, stable temperature control in each section, slight error.

- The injection system is designed with double injection cylinders, double seat cylinders, and double guide pillars, with smooth movement and high injection precision.

- Special screw and tube set design, suitable for different injection process requirements.

- Configuration of high torque, low noise hydraulic motor, so the plasticizing ability is more excellent.

- High-quality self-lubricating bearings are used in movable parts to make machine maintenance easier.

| Specification | Clamp Force (T) |

|---|---|

| MH-2R-45T.jpg | 45 |

| MH-2R-60T.jpg | 60 |

| MH-2R-85T.jpg | 85 |

| MH-2R-120T.jpg | 120 |

| MH-2R-160T.jpg | 160 |

| MH-2R-200T.jpg | 200 |

| MH-2R-300T.jpg | 300 |

Rotary Table Injection Schematic

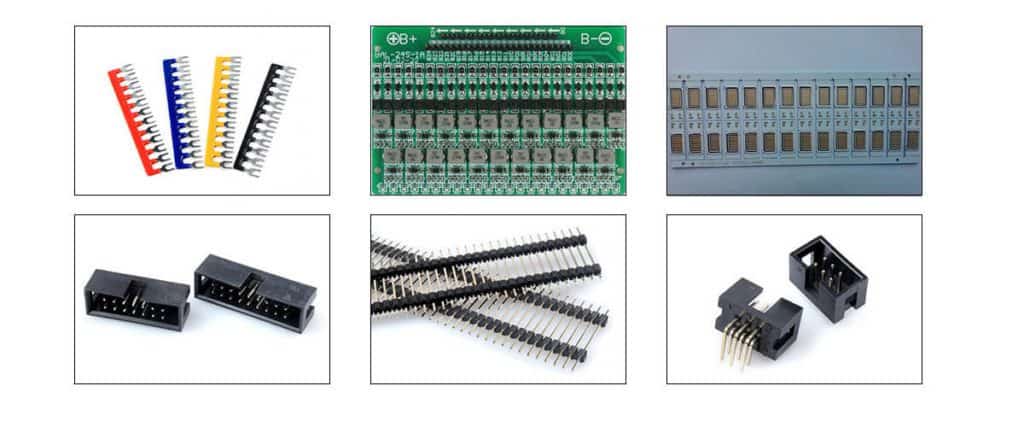

Rotary Table Injection Sample Display