Sliding Table Injection Machine

Sliding table injection machine includes single sliding table plastic injection moulding machine and double sliding table plastic vertical injection machine, the following are their differences:

Single Sliding Table Injection Machine

Single Sliding Injection Machine's Description

Application

Feature

Parameters Table

Specification For A Complete Clamping

Application

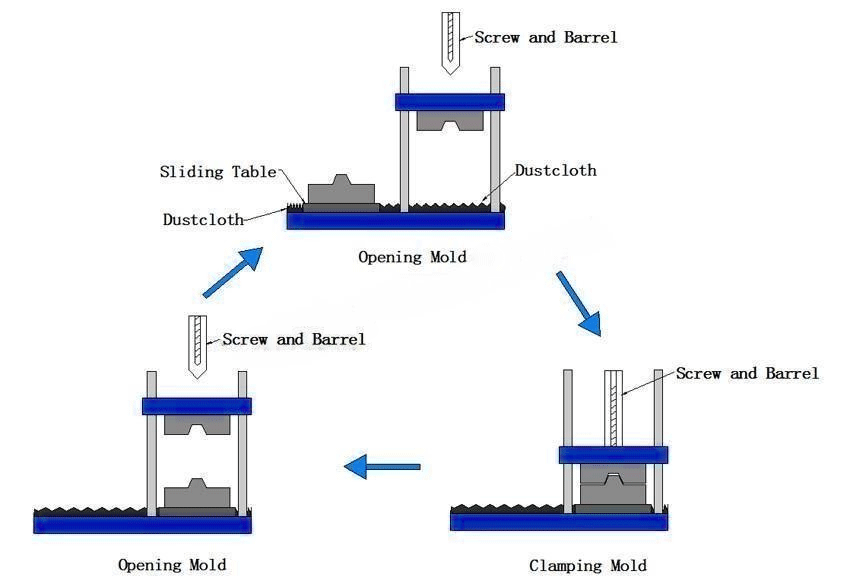

- A single sliding mold is added to the standard series to allow the machine to complete the cycle of sliding movement of the lower mold and the single slide plate. After the mold is closed, the lower mold automatically slides to the front of the operator, which is more convenient for operation. The ejection of the finished product is also completed externally. The safety is higher, and it is suitable for more products.

Feature

- Clamping force: 10T~500T.

- Injection weight: 35g~850g.

- Vertical four columns calmping, vertical injection.

- Suitable for insert injection molding process.

- Single table sliding out of locking area product, put insert part; sliding mode into the lock mold injection, effective to improve production flexibility and safety.

- We can upgrade to servo motor for customer’s need.

- The actual energy save 50%~70%

Parameters Table

| Specification | Clamp Force (T) |

|---|---|

| MH-45T-1S.jpg | 45 |

| MH-60T-1S.jpg | 60 |

| MH-85T-1S.jpg | 85 |

| MH-120T-1S.jpg | 120 |

| MH-160T-1S.jpg | 160 |

| MH-200T-1S.jpg | 200 |

Specification For A Complete Clamping

Single Sliding Injection Schematic

Double Sliding Table Injection Machine

Previous slide

Next slide

Double Sliding Plastic Injection Machine's Description

Application

Feature

Parameters Table

Specification For A Complete Clamping

Application

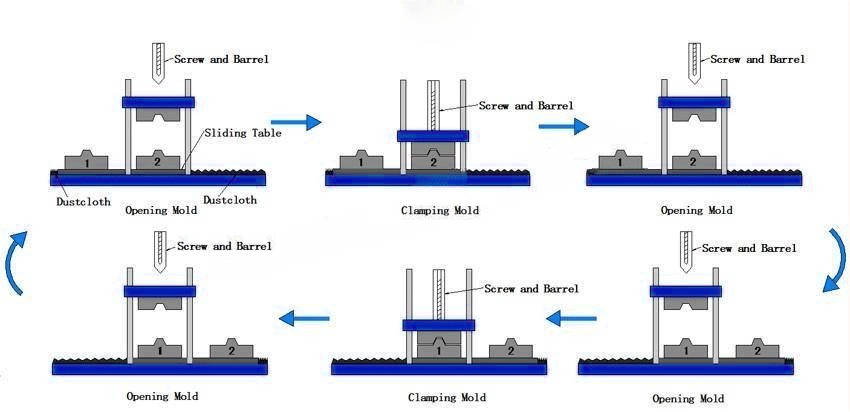

- Application of double slide vertical injection molding machine: Mainly used in injection molding of inserts and suitable for small injection plastic parts without inserts. Vertical mold clamping, upright injection, convenient for inserting parts; double-station sliding plate (1 upper and 2 lower molds), increased production capacity; fast left and right sliding, accurate positioning, the main advantage is high molding efficiency.

Feature

- Clamping force: 10T~500T

- Injection weight: 35g~850g

- Vertical four columns calmping, vertical injection.

- Suitable for insert injection molding process.

- One top mold, 2 bottoms mold design, table slid out, put insert part into outer mold and inner mold injection at the same time, effective to improve production capacity, flexibility, and safety. We can upgrade to servo motor for customer’s need. The actual energy save 50%~70%.

Parameters Table

| Specification | Clamp Force (T) |

|---|---|

| MH-45T-2S.jpg | 45 |

| MH-60T-2S.jpg | 60 |

| MH-85T-2S.jpg | 85 |

| MH-120T-2S.jpg | 120 |

| MH-160T-2S.jpg | 160 |

| MH-200T-2S.jpg | 200 |

Specification For A Complete Clamping

Plastic Double Sliding Table Injection Schematic

Sliding Injection Sample Display