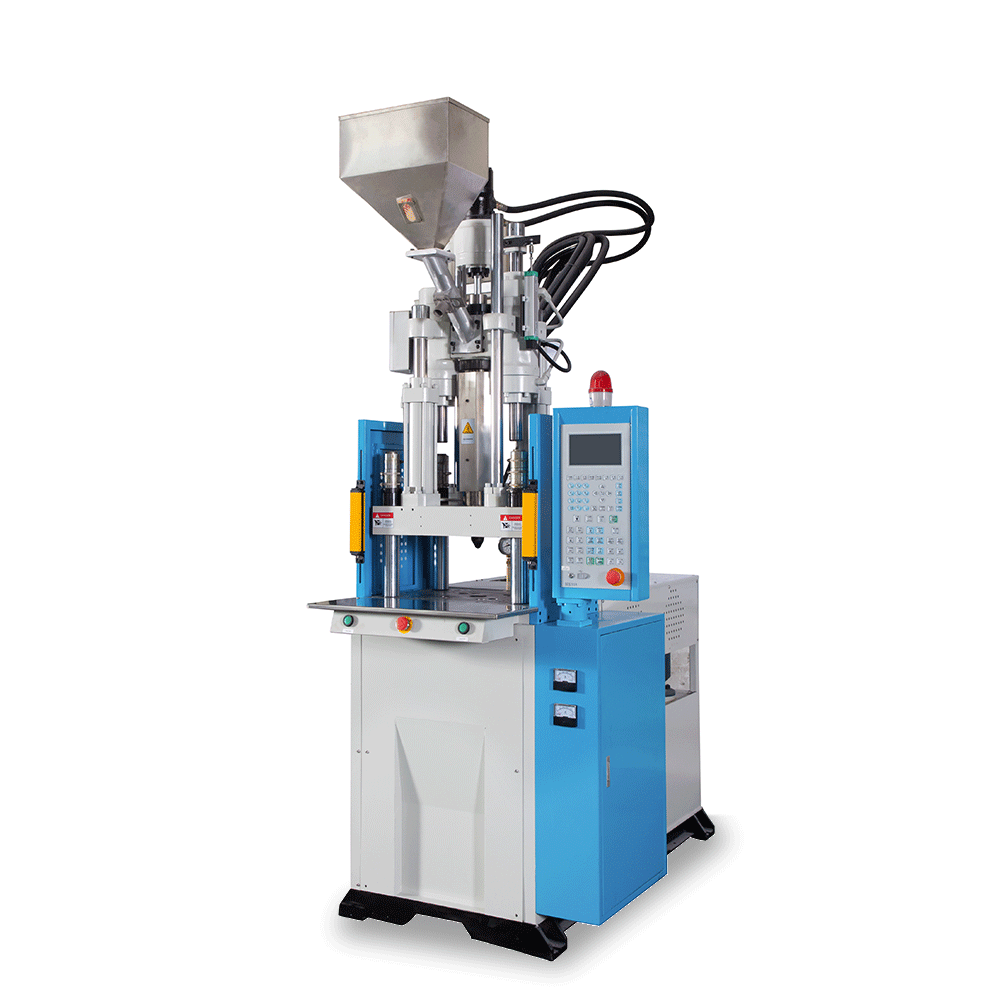

Standard Plastic Injection Molding Machine

Standard injection molding machine is suitable for meters, electronic parts, connectors, power cords, headphone cords, headphone plugs, headphone sockets, connectors, etc.

Standard Plastic Injection Molding Machine's Description

Application

Characteristics

Feature

Parameters Table

Specification for a complete clamping

Application

- MH standard machine, also called power cord molding machine, suitable for insert molding of available electrical plugs and electronic parts.

- Two-stage or three-stage temperature control, step-less adjustment of injection speed, back pressure, etc., are more suitable for precision plastic parts molding.

- Fast mold clamping/low-pressure, slow mold closing. When the mold lock is abnormal, the mold will be opened automatically. This particular safety design can protect the mold.

- The lower mold is fixed, the upper mold is movable, which has a good positioning of the molded insert in the mold. The finished product has a hydraulic ejector device, which is very convenient and easy to take out.

Characteristics

- Vertical mold closing, vertical injection, suitable for insert molding.

- Fast mold clamping, low-pressure safety mold clamping, abnormal automatic mold opening, unique safety design.

- Low-voltage safety protection function: The uniquely designed zero-pressure slow mold closing technology protects personal safety and ranks first in the industry. If there is a foreign object between the upper and lower molds, the mold will not be forced to lock, and the mold opening will be automatically protected.

- Automatic fault display, adjustment, and detection are straightforward.

- Imported parts are used for electric control and hydraulic pressure, which are quiet, precise, and durable.

- Multi-stage temperature control, multi-stage injection pressure, injection speed, back pressure step-less adjustment, suitable for precision plastic parts molding.

- Equipped with a hydraulic ejector device for finished products.

- (Lifting seat type) The shooting seat can be automatically raised and lowered and has an automatic cleaning device to replace molds and raw materials.

Feature

- Clamping force: 15T to 200T

- Injection weight: 35g to 850g

- Vertical four columns clamping, vertical injection.

- Suitable for insert injection molding process.

- We can upgrade to servo motor for customer’s needs.

- The actual energy save 50%~ 70%.

Parameters Table

| Specification | Clamp Force (T) |

|---|---|

| MH-15T.jpg | 15 |

| MH-20T.jpg | 20 |

| MH-35T.jpg | 35 |

| MH-45T.jpg | 45 |

| MH-60T.jpg | 60 |

| MH-85T.jpg | 85 |

| MH-120T.jpg | 120 |

| MH-160T.jpg | 160 |

| MH-200T.jpg | 200 |

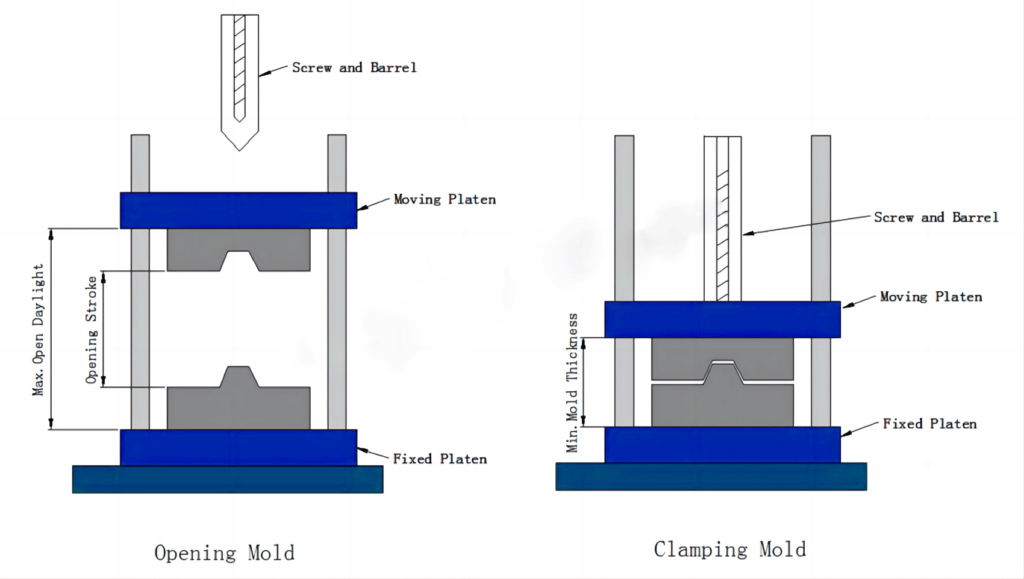

Specification for a complete clamping

Standard Injection Schematic

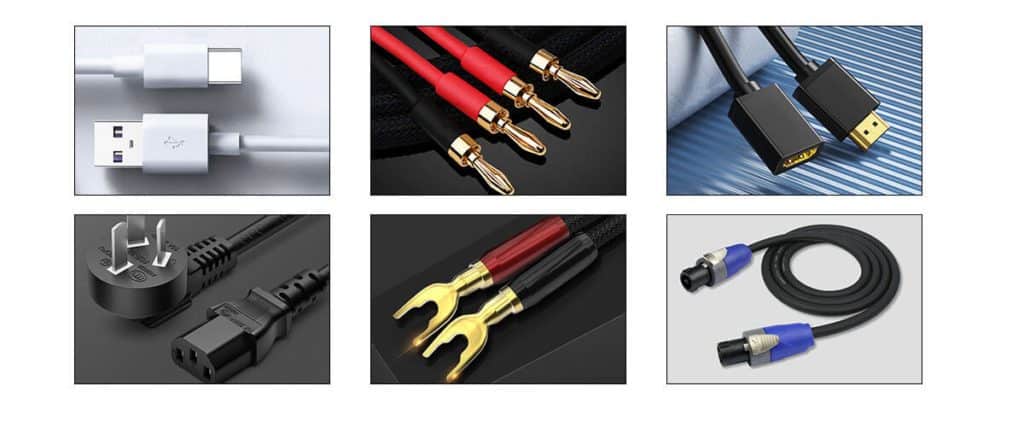

Standard Injection Sample Display